- Main Application:As a new type high efficiency and high precision mixing equipment, this machine is widely used for mixing of powdery or paste materials in pharmaceutical, chemical and feed trades etc. Working principle:The machine consists of single screw and type S blade. It is featured with large agitating scope, high mixing speed, no dead angle. It is more suitable for mixing materials with a great disparity in specific weight and mixing proportion. Model Barrel volume Max loading volume Max loading weigh Mixing time Material size Motor power Overall dimension Weight DLH100 100L 60L 60kg 0-99min 20-350mesh 2.2kw ¢700*1400mm 300kg […]

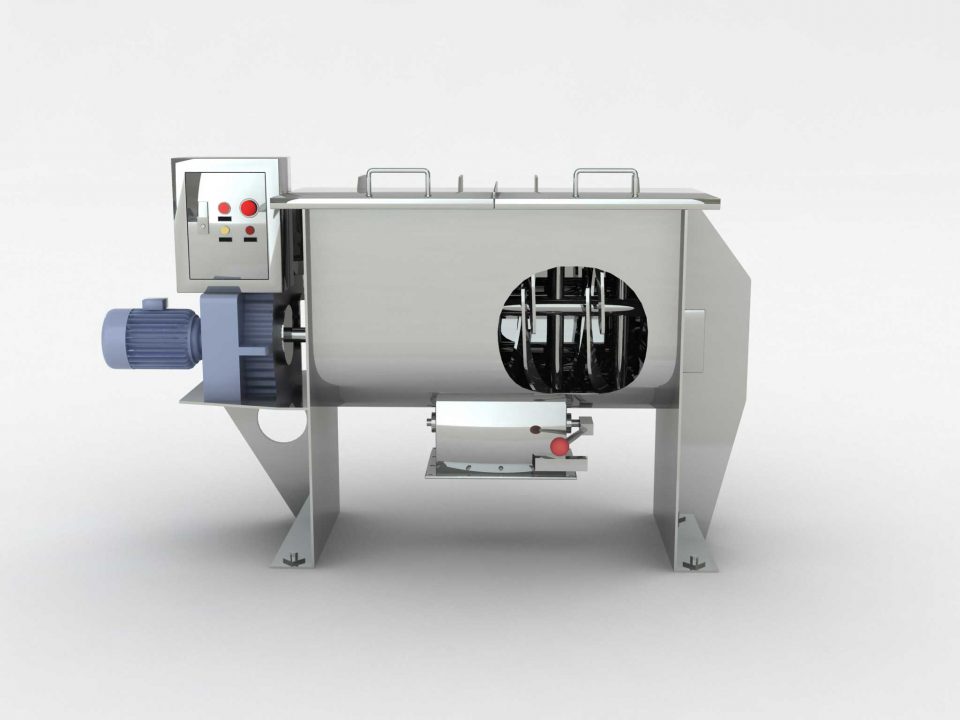

- Main Application:WLDH Horizontal Ribbon Mixer is a pioneer product researched and a new high-efficiency mixer. It is widely used in the solid-solid (powder material) and solid-liquid (powder material & fluidity material) mixing in the field of chemical industry, pharmacy, foodstuff industry, etc. Features:WLDH series mixer is mainly comprised of mixing barrel , spiral ribbon and driven parts. The spiral ribbon is made of two layers. That is, the inner ribbon makes the material move outwards, while the external ribbon makes the material move inwards which forms a good circulation of material. Ribbon moves so circumferentially that the mixer could achieve […]

- Main Application:As a whole stainless steel horizontal tank type mixer, this machine is widely used for mixing of powdery or paste material in pharmaceutical chemical and foodstuff industries. Working principle:S type agitating paddle is rotated, through mechanical driving, which pushes the material turn repeatedly and mix uniformly, operate with electrical control, it can set mixing time to make automatic stop and electric discharge upon expiration, thus improving the mix quality of each batch of material and reaching the high homegeneous mixing. Model Type of paddle Barrel volume Max loading volume Max loading weigh Speed of agitating paddle Turning angle […]

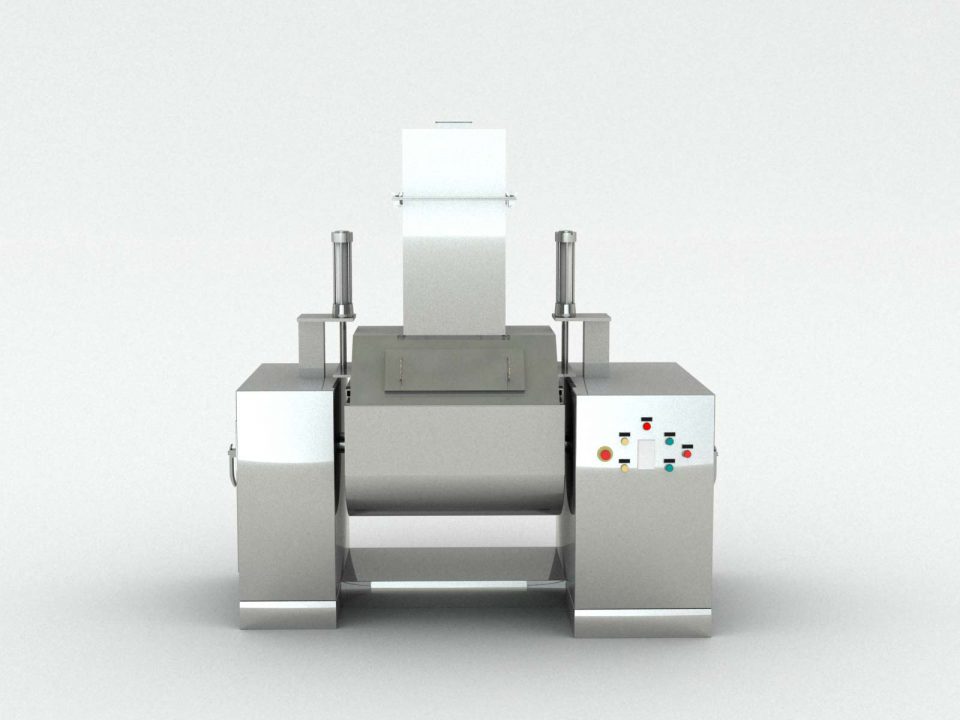

- Main Application:The machine is horizontal double paddle tank type mixer which is widely used in pharmaceutical, chemical and foodstuff industries for mixing powdery or paste material especially for big viscosity and high homogeneous material. Working principle:The machine let the S type paddle make opposite movement to impulse the material and mix by the active and passive shaft. The machine is made of stainless steel. You can set the mixing time and the machine will stop automatically. It is discharged by electromotion which will cause the working intensity of workers. The machine will reach the high homogeneous mixing. Model Barrel […]

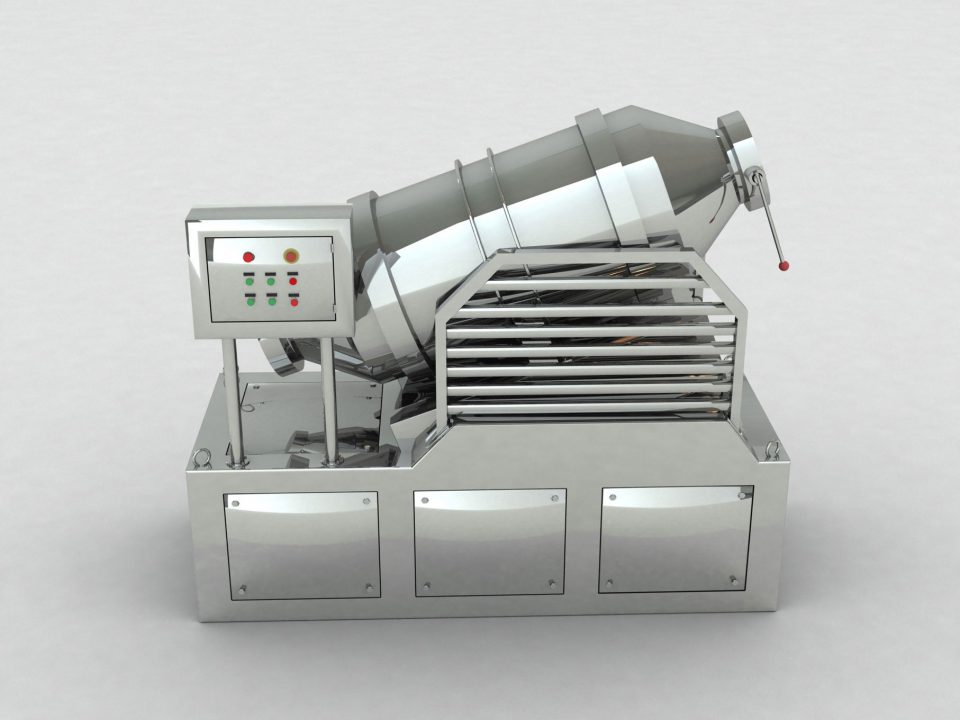

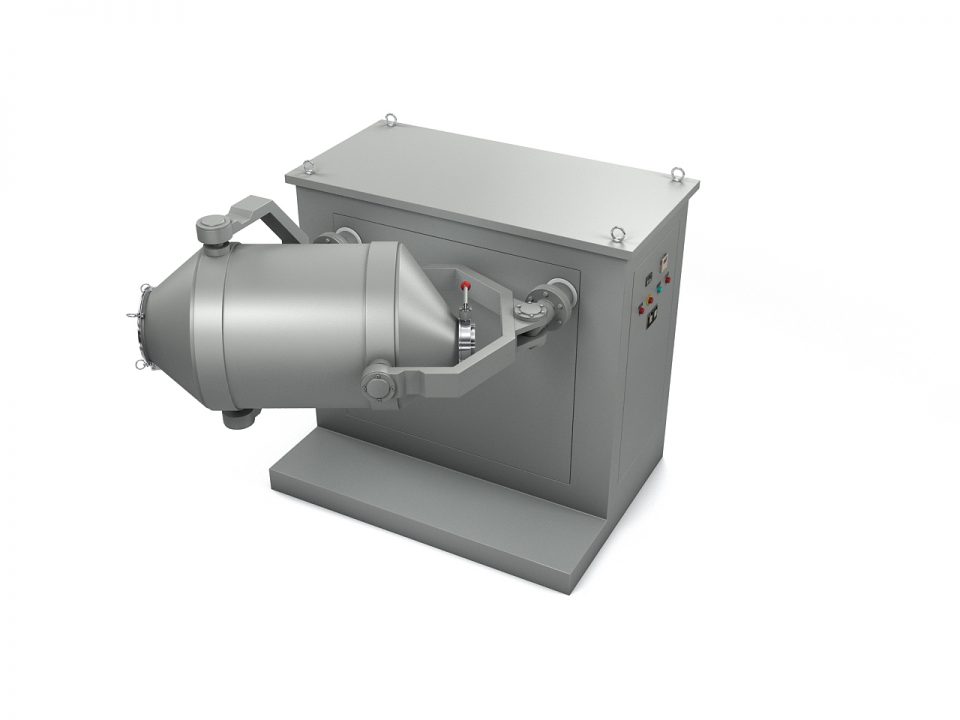

- Main Application:The mixer is suitable for the mixing of dry granule materials for pharmaceutical, chemical industries, etc., especially for the mixing of materials with high tonnage. Working principle:The mixing tank is a cylinder-shape barrel without any stirring device inside, which makes the self-rotation around its axis and also produces turnover swing movement around its plane axis synchronized, therefore, the target materials inside the barrel could be mixed diffusely and moveable, it is featured with short mixing time, good uniformity, big output, convenient to discharge, etc. Model Barrel volume Max loading volume Max loading weigh Mixing time No.of rotation No.of […]

- Main Application:As a whole stainless steel horizontal tank type mixer, this machine is widely used for mixing of powdery or paste material in pharmaceutical chemical and foodstuff industries. Working principle:S type agitating paddle is rotated, through mechanical driving, which pushes the material turn repeatedly and mix uniformly, operate with electrical control, it can set mixing time to make automatic stop and electric discharge upon expiration, thus improving the mix quality of each batch of material and reaching the high homegeneous mixing. Model Type of paddle Barrel volume Max loading volume Max loading weigh Speed of agitating paddle Turning angle […]

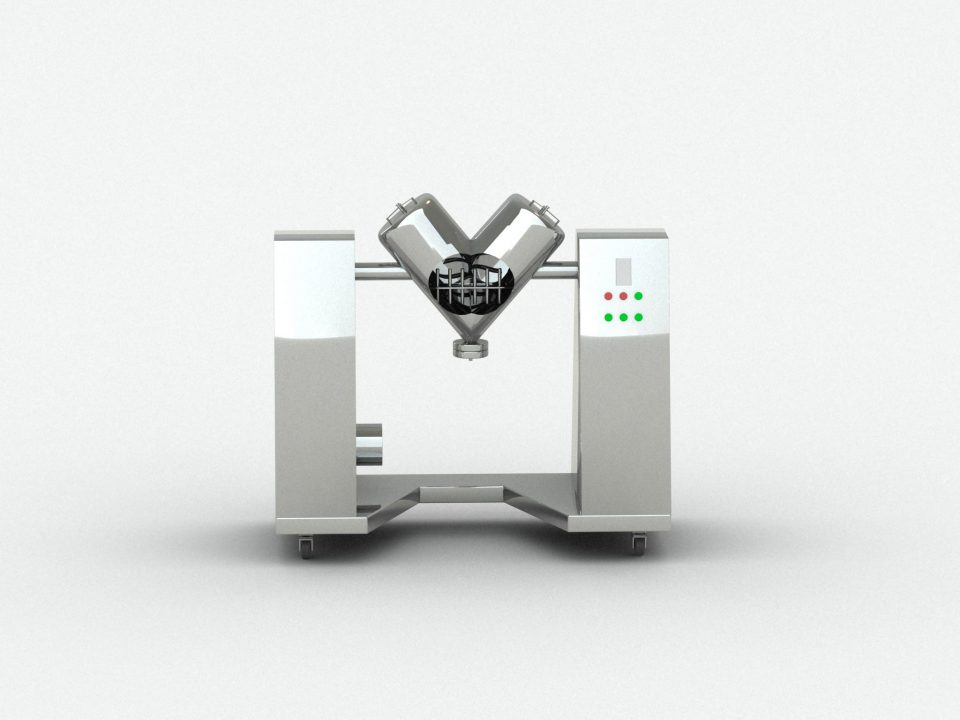

- Main Application:Based on importing, absorbing and digesting the new technology of foreign countries, our company developed the VI type forced mixer used for pharmaceutical, foodstuff and chemical trades etc. Features:This machine can mix coagula of relatively fine powder consisting of two kinds of materials or material with certain amount of moisture content. Model Barrel volume Max loading volume Max loading weigh Mixing time Motor power Barrel speed Agitation speed Overall dimension Weight CH-300VI 300L 120L 120kg 0-99min 1.1*2.2kw 12r/min 500r/min 2100*650*1850mm 450kg CH-500VI 500L 200L 200kg 0-99min 3*2.2kw 12r/min 500r/min 2700*800*2050mm 480kg CH-1000VI 1000L 400L 400kg 0-99min 5.5*2.2kw 10r/min […]

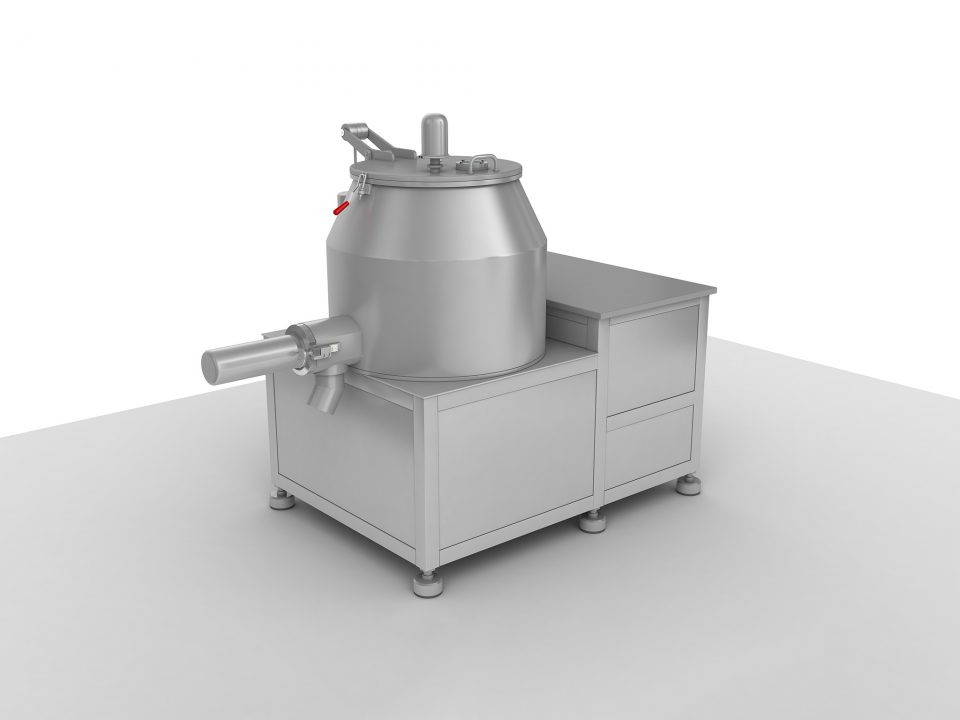

- Main Application:Powder material and the bottom of the binder in a cylindrical container by mixing oar mix into wet soft wood, and the offset of wet crushing blade cut into uniform particles. Features::1, the machine adopts the bedroom cylinder structure, the structure is reasonable. 2, inflatable, drive shaft sealing, when cleaning can be changed into water. 3, fluidized granulation, granulating approximate spherical, liquidity is good. 4, the traditional process, 25% of adhesive can be reduced, the drying time shortened. 5, 2 minutes per batch for mixing, granulation, 1-4 minutes efficacy 4-5 times higher than that of traditional craft. 6, completed […]

- Main Application:This machine is applicable for mixing of powdery and granulate material in pharmaceutical, chemical foodstuff, ligh industry, electronic, mining and metallurgy, national defense industry and scientific research institutes. Working principle:This machine is composed of base, governor motor shaft, rotary connecting rod and barrel etc., material barrel is driven by the positive shaft to make complex movement including horizontal move, rotation and roiling etc, which makes the material moved to 3 directions along the barrel, therefore, highly uniform mixing of various material is realized. This machine is a kind of full closed high effcient energy saving mixer without germ and […]

- Main Application:ZS series lamination screening is applied for continuous screening of powder and inhomogencous granulates in such trades as pharmaceutical, chemical and food stuff etc. Working principle:This machine is comprised of hopper,vibrating chamber, coupling and motor etc., Where the vibrating chamber is composed by eccentric wheel,rubber part, spindle and bearing etc. when eccentric weight is conveyed to the centerline of spindle through motor driving ,it generates centrifugal force under unbalanced state,by which, material is forced to form regular eddy inside, and the amplitude of the weight adjuster can be regulated according to different material and screens .the whole machine features […]

- Main Application:Designed and modified by importing the advanced foreign technology and in combination with GMP standard, this machine is widely used for grading and screening of industrial raw materials in such trades as pharmaceutical, chemical, foodstuff, metallurgy and electronics etc. Working principle:This machine is comprised of screen box, Vibration source and damper, vibrating frame and screen box are connected with 4-12 group soft rubber dampers fixed up and down, and the centrifugal force is generated therein, the floating amplitude is controlled by the damper, by which, material realizes a process of throw and lamination filtration downward, and therefore reaching the […]

- Main Application:Being an ideal screening equipment applied in pharmaceutical, chemical, foodstuff trades etc.. this machine is particularly used for screening of high fiber, high viscosity, high humidity, electrostatic and easy blocked materials. Working principle:Material is fed into the screen box through screw conveyor, continuous rotation of the vane pushes the material forward, fine material is fallen from the screen, and the coarse material is further advanced and discharged from the coarse oblique port, and thus reaching the ideal screening effect. Model Production capacity Meshes screen Motor power Spindle speed Weight LXS-250 60-800kg/h 20-300mesh 5.5kw 960r/min 250kg LXS-350 200-1800kg/h 20-300mesh […]