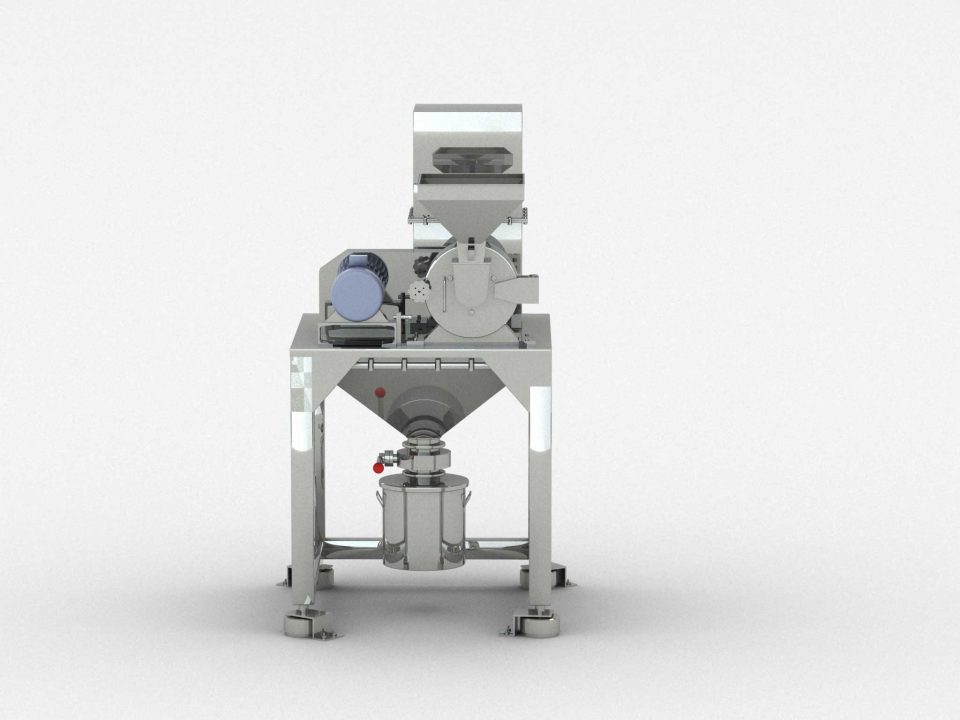

Main Application:Comprised of main frame, auxiliary machine and electrical control cabinet, this machine has such performances as winnowing, screen or mesh free, uniform size and continuous operation, and has reached the international advanced level, thus being widely used for material crushing in pharmaceutical, chemical and foodstuff trades etc..

Working principle:The material is fed into the crushing chamber by a screw conveyor, cut and crushed by high speed rotating blade and conveyed to the cyclone separator by means of negative pressure air conveyance before being discharged by bag type collector, and the dust is filtered and recovered by dust collector through filter barrel Having no dust flying during production, it can improve utilization rate of the material and reduce the cost of enterprise.

| Model | Production Capacity | Feeding Size | Output size | Total power | Main Speed | overall dimension | weight |

|---|---|---|---|---|---|---|---|

| WFJ-300 | 10-100kg/h | ≤10mm | 60-450mesh | 13.5kw | 5800r/min | 4200*1200*2700mm | 1000kg |

| WFJ-450 | 50-250kg/h | ≤10mm | 60-450mesh | 19.3kw | 5200r/min | 4300*1350*2700mm | 1500kg |

| WFJ-520 | 80-500kg/h | ≤10mm | 60-450mesh | 39.05kw | 5000r/min | 7920*1480*3290mm | 2500kg |

| WFJ-630 | 200-1500kg/h | ≤10mm | 60-450mesh | 75.3kw | 4500r/min | 9500*1800*3730mm | 3200kg |