- Main Application:It’s applied for drying and dehumidification of material in such trades as pharmaceutical, chemical foodstuff, light industry, heavy industry etc., as well as heating and dehumidification of product, including raw medicines, original medicines, doses, traditional Chinese medicine tablet, powder, granulate, electuary, ball packing bottle, pigment, dyestuff, dried vegetable, food, plastic resin, electric clement and baking finish etc. Model RXH-B-O RXH-B-I RXH-B-Ⅱ RXH-B-Ⅲ RXH-B-Ⅳ Drying capacity 60kg 120kg 240kg 360kg 480kg Power 0.45kw 0.45kw 0.9kw 1.35kw 1.8kw Steam consumption 10kg/h 20kg/h 45kg/h 71kg/h 90kg/h Radiation area 5m 20m 40m 80m 100m Blast 3450mh 3450mh 6900mh 10350mh 13800mh Temperature deviation […]

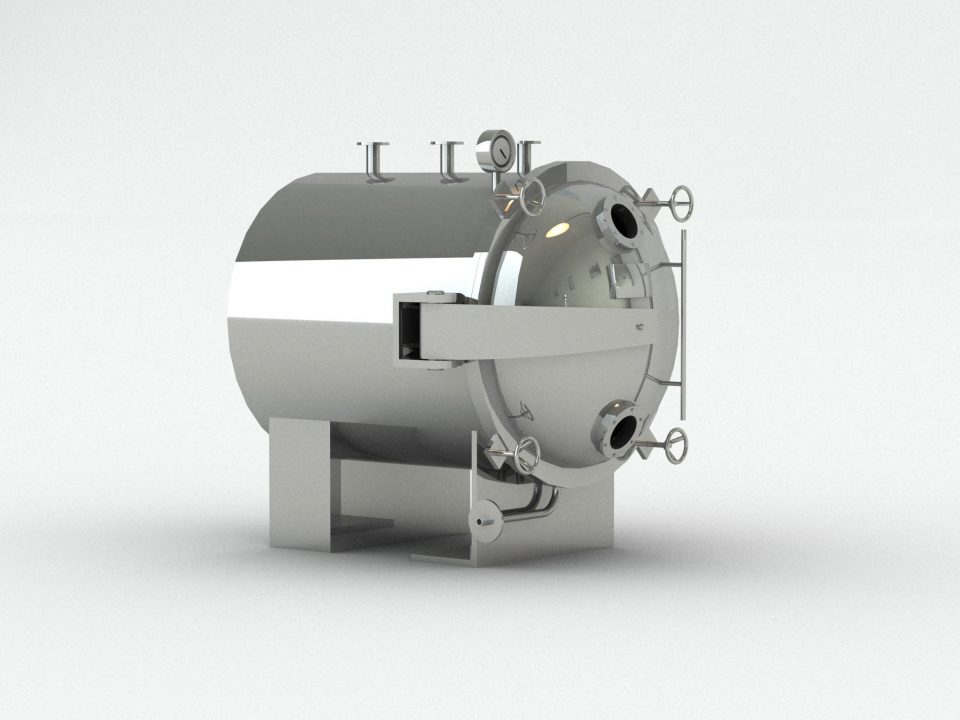

- Features:Vacuum dry is to let the raw material to be dried at vacuum condition heating and drying. It used vacuum pump to pump damp and make the working chamber form vacuum status. Therefore the dry speed pf raw material is quickened and the energy is saved greatly. Vacuum dry is divided into static and dynamic drier. Model FZG round vacuum drier or Model FZG square vacuum drier belongs to static drier. Model SZG double cone rotating vacuum drier belongs to dynamic drier. When raw material is dried in static drier, raw material is in static state and its shape can […]

- Main Application:This machine is used for boiled drying of granulate material with site of 0.16mm, and is applicable for quick drying of wet granulate and powdery material of finished products and intermediate(semi-finished products) in such trades ad pharmacy, foodstuff, light industry and chemical etc. Working principle:Under the draught of fan ,natural air passes through purification cabinet and heater, and form high speed airflow in small hole of material bed board, which makes the material into boiled(fluidized)status and then makes the moisture(or solvent)in material vaporized(or volatilized)quickly, thus realizing the purpose of drying. Stirrer is designed inside hopper, material boiling is free […]

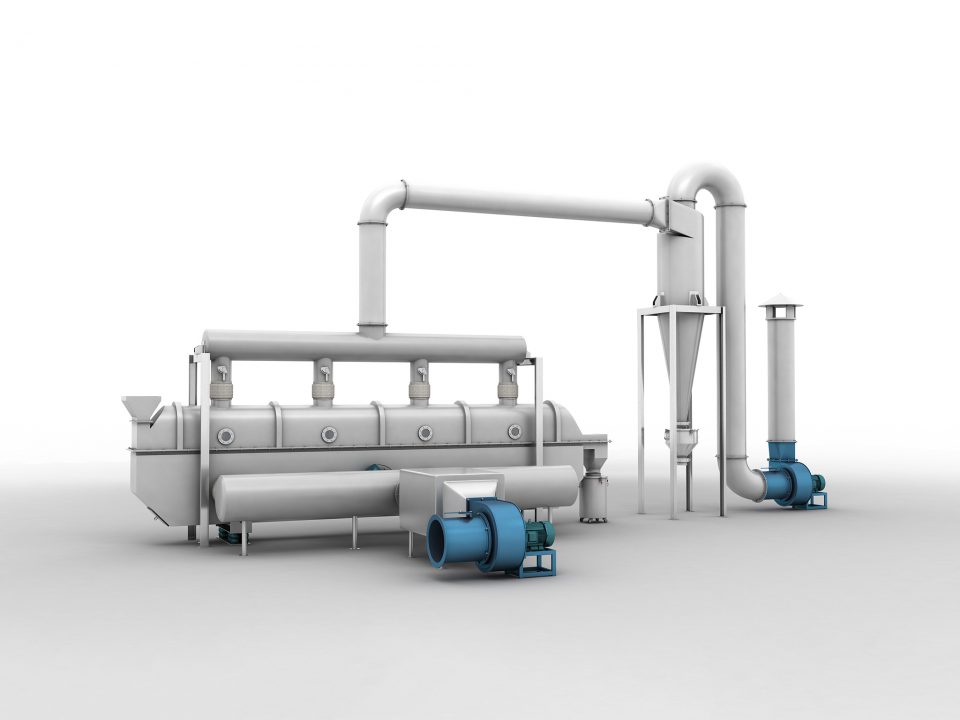

- Main Application:◆ Pharmaceutical and chemical industries: all kinds of press tablet and granule, boric acid, borax, dihydroxybenzene, malic acid. maleic acid and so on; ◆ Foodstuff and construction material industries: monosodium glutamate, edible sugar, edible salt, mine residue, bean, seeds and so on ; ◆ It can also used for raw materials to add damp or cooling and so on . Working principle:Raw material is fed into the machine from the inlet and moves forward continuously along with the level of fluidizedbed under the action of vibration.The hot airpasses through fiuidi-zed-bed and carries out heat exchange with damp raw material. […]

- Main Application:The machine is suitable for drying the material in pharmaceutical chemical foodstuff, elastic gum, electronical industries dewatering vegetable, particle feed, gourmet powder, shredded coconut stuffing, organic color, compound rubber, acryl fibre, medicine product, medicine material , small wooden product, plastic product, aging and solidification for the electronic component and device. Working principle:The materials are uniformly put on the mesh-belt by the material charger. The mesh-belt uses generally 12-60mesh stainless steel wire net and it is drawn and moved inside the direr by a transmission device. The drier is composed of several units, the hot air is circulated separately.Some exhausted […]

- Main Application:LPG series high-speed centrifuge atomizing drier is a special equipment and is suitable for drying emulsion, suspending liquid, liquor and so on. Particularly it has unique advantage for drying polymers and resins; dyestuff and pigment; ceramics, glass; derust agent; pesticide; carbohydrate, dairy products; detergent and surfactant; fertilizer, organic compound, inorganic compound and so on Working principle:Air is turned into hot air through air filter and heater into hot air distributor at the top of dry chamber and then enters into dry chamber spirally and evenly, At the sametime liquid of raw material is sent to centrifugally tomizer at the […]

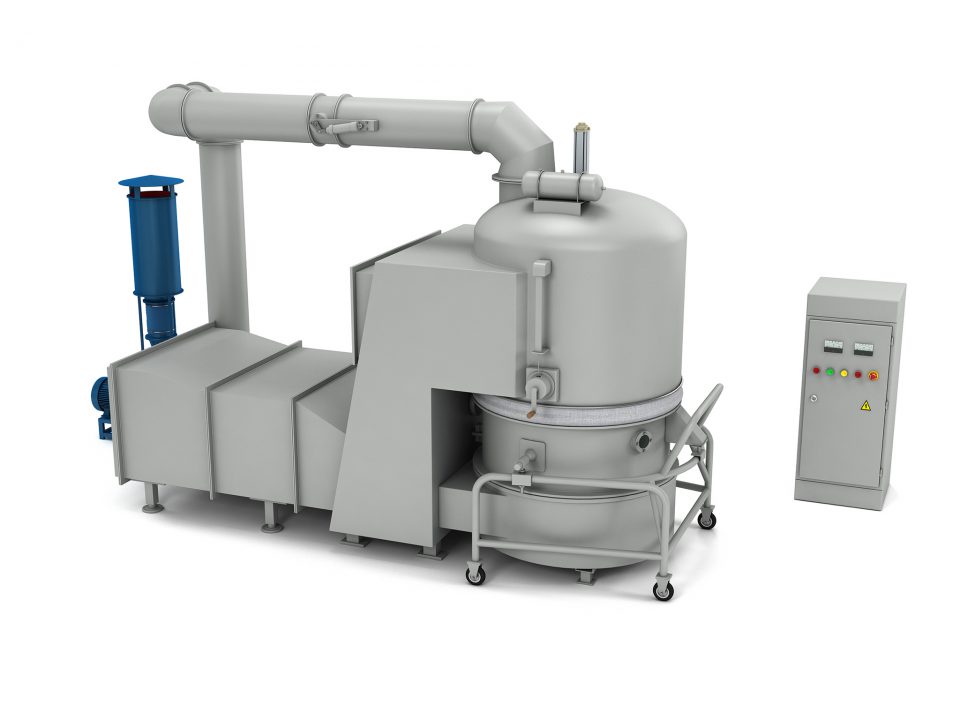

- Main Application:This company produces the boiling dryer into the explosion protection and the two, their respective applicable to different production technology and production requirement can be meet different production needs. Working principle:Within the machine use centrifugal fan to make the bed form the negative pressure, the cold air suction, cold air by coarse effect, and high efficiency filter to remove tiny dust particles, and then into the heat for heating, air to enter air heated to the desired set temperature (using XMT – 192 temperature control instrument set to the required temperature, ma current signal 0-10 to DQ – 100 […]

- Main Application:Its mainly used for drying and mixing of material in pharmaceutica chemical and foodstuff trades etc. Features:This machine has good drying and mixing effect to heat sensitive, easy oxidizing and non-crystalline damage material, solvent recovering material and strong irritating and toxic material. With high drying speed and uniform product drving, it has no pollution to the material and is operated and cleaned easily, in addition, the optimize designed seal has good sealing effect and convenient maintenance. Model Total volume Speed Power Loading coefficeient Heating media Working pressure Working temperature Innertank Jacket Innertank Jacket SZG-30 30L 10r/min 0.8kw ≤50% […]